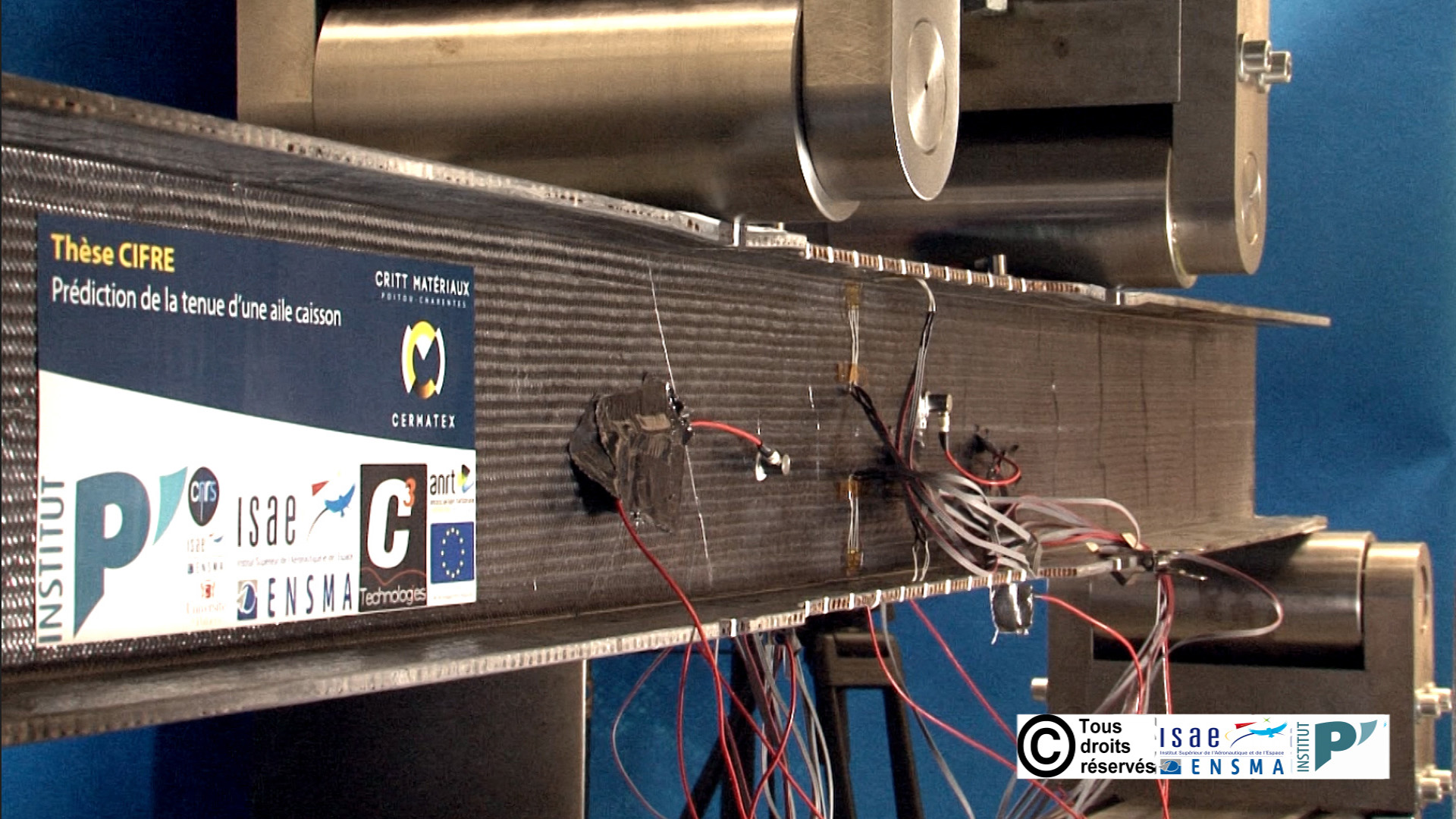

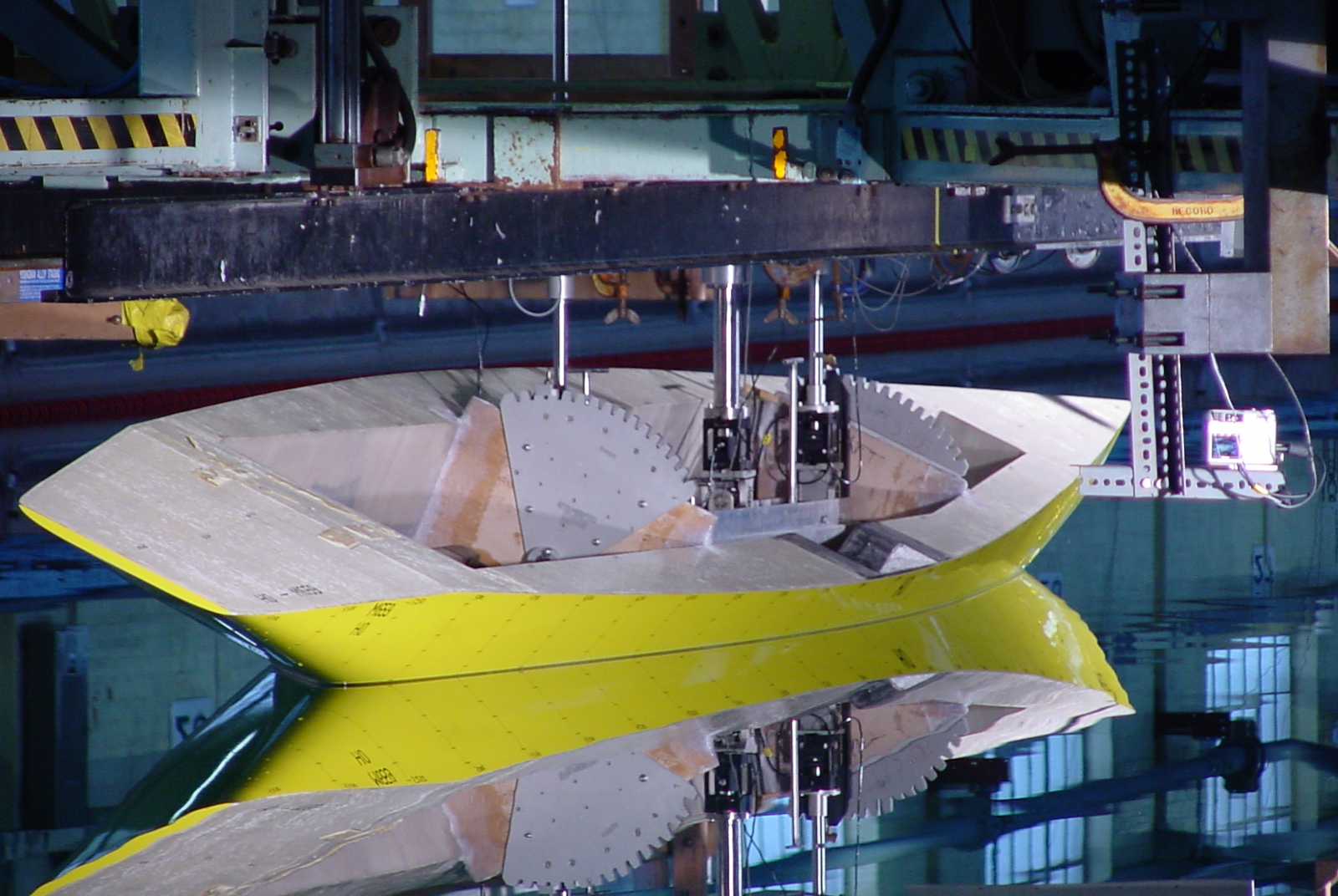

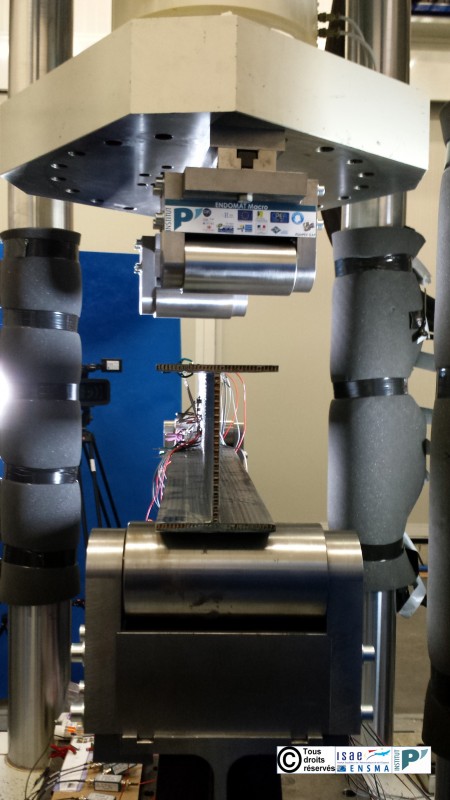

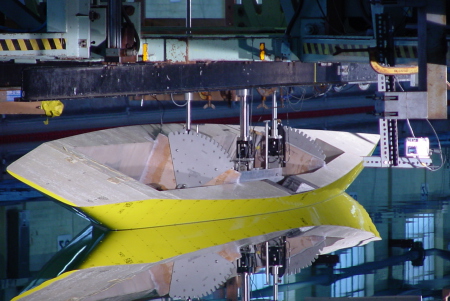

Production of test pieces, prototypes, and manufacture of models made from composite materials

Be it in-house or in cooperation with research centres and other companies, C³ Technologies puts R&D at the heart of its strategy to ensure that the very latest and most technologically advanced processes and materials are always used.

From the production of test pieces allowing the specific features of composite materials to be studied, to prototypes and the study of new design and manufacturing processes, C³ Technologies is here to help and advise on the use of composite materials in your next R&D project.

C³ Technologies has been granted an Innovation Tax Credit that it can reinvest in further R&D.