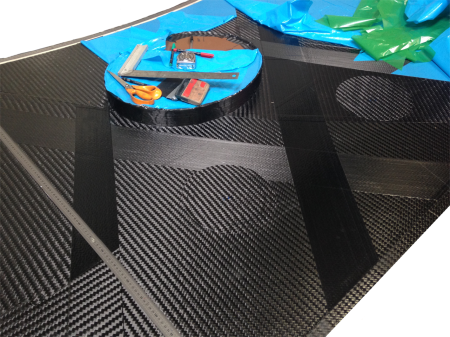

Materials used by C³ Technologies

Composite materials offer great diversity in terms of their nature and applications.

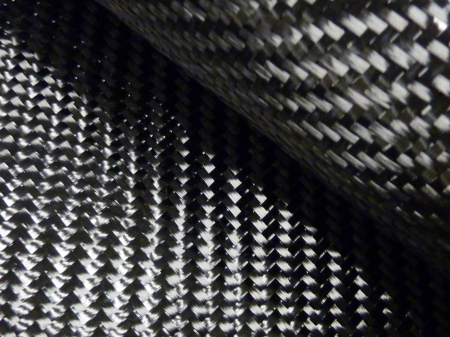

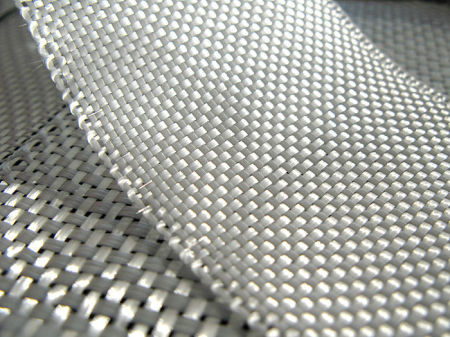

C³ Technologies currently works primarily with carbon fibre, a composite material that provides the highest strength in return for the lowest weight. Many types of carbon are used, falling into two broad categories – dry fabric and pre-impregnated fabric. We also use glass fibre, Kevlar, and indeed any other materials needed for the manufacturing process (Nomex, PVC foam, epoxy resin, etc).