C³ Technologies’ quality control procedures

In order to meet our client demands and provide top quality products and services, C3 Technologies attaches great importance to the various elements needed to operate an efficient quality control system. From the very first commercial exchanges through to delivery of the final product, we ensure every stage of every operation is fully monitored and traceable and that the technical specifications and planning requirements are respected.

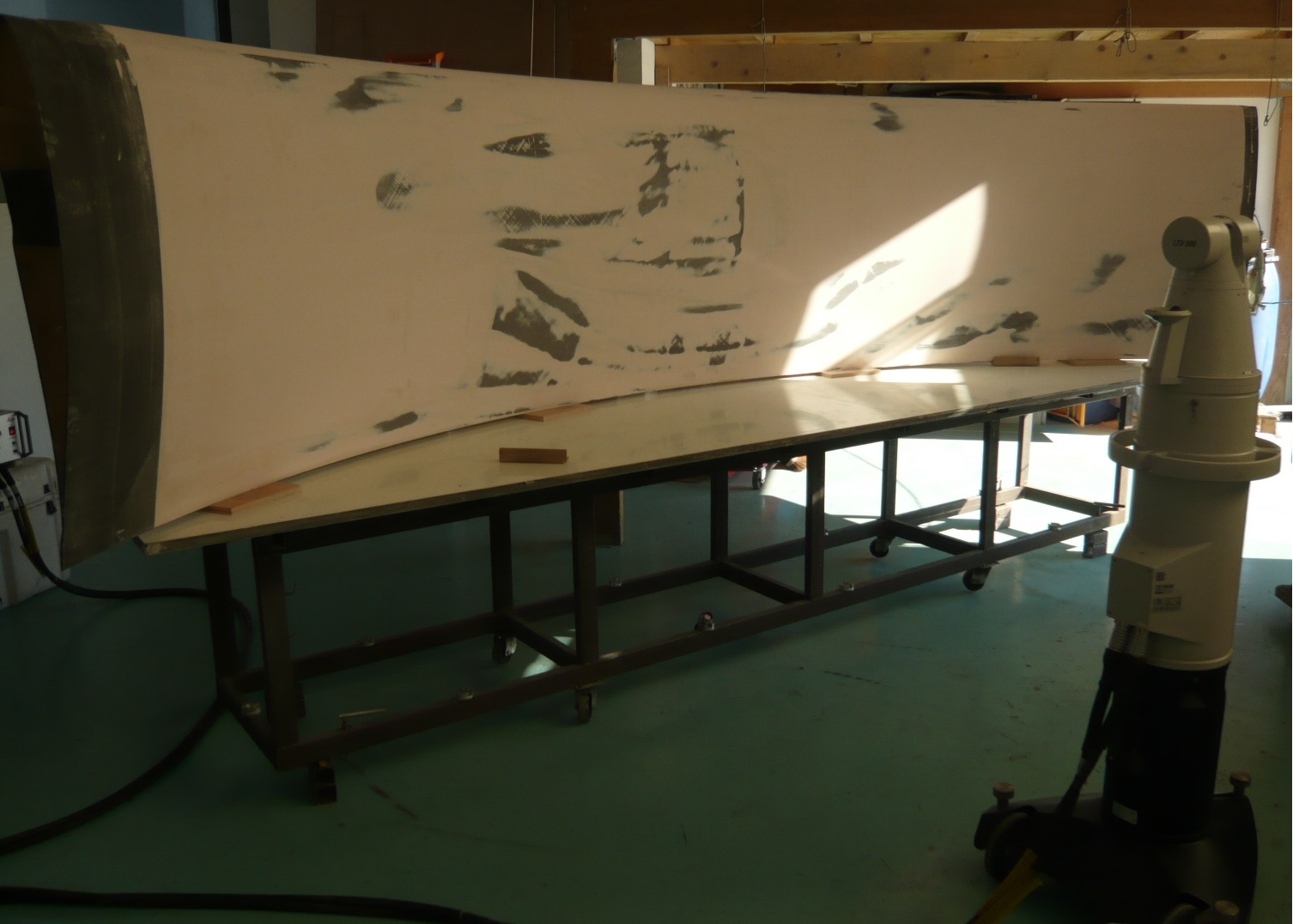

Here is an overview of the principle steps we take to ensure the quality of the services we supply